by M. Thomas Davis

The Russian invasion of Ukraine, along with increased tensions in the Middle East and the Indo-Pacific region, has generated many debates. Debates about the stability of the international order, the cohesion of NATO, and many others. But for the United States, one significant debate regards the size and expansibility of the American defense industrial base. It’s a discussion that is well past due.

Last year, Under Secretary of Defense Colin Kahl testified to Congress that, “What the Ukraine conflict showed is that, frankly, our defense industrial base was not at the level that we needed it to be to generate munitions.” But the challenge with ammunition is more symptom than cause, in economic terms something of a “leading indicator.”

The ammunition shortage reflects the reality of a production base that over the past thirty years has shrunk from sixteen to five ammunition plants. But that is merely a specific reflection of a general concern applicable to aircraft, surface ships, submarines, missiles, and ground combat vehicles.

Simply put, the basic question is this: Is the current American defense industrial base large enough? And if not, what should we do about it?

Let’s go back to the origins of an enduring myth – the enormous size of the American “military industrial complex.”

When President Dwight Eisenhower gave his farewell address in January 1961, his comments included the caution, “we must guard against the acquisition of un-warranted influence, whether sought or unsought, by the military-industrial complex.” Although Eisenhower also cautioned against a lack of military preparedness, his “military-industrial complex” comment became the line for which the speech is remembered. And despite the passage of more than sixty years, the phrase has endured even though the “complex” itself has not.

At the time of Eisenhower’s speech some fifteen companies in the Fortune 100 were engaged in the defense effort. But, as a group, those fifteen were operating at a loss as the companies and their pentagon customers were still finding a moving “price point.” The defense business had changed after World War II, shifting from a largely government domain – now known as the “arsenal system” — to the commercial sector. Tellingly, Eisenhower’s first two defense secretaries, Charles Wilson, and Neil McElroy, were former corporate executives.

When President Ronald Reagan initiated his “defense build-up” in 1981, the defense industrial base had experienced enormous growth. There were over forty major companies engaged in it, fourteen of them able to design and manufacture high-performance military aircraft. Today there are only three.

Since the end of the Cold War, the American defense industrial base has compressed from those forty or more firms down to five, driven by changing strategic circumstances and federal budget priorities.

The 2023 Fortune data finds that in its top 100 there are only three firms listed in the Aerospace and Defense (A&D) sector – Raytheon Technologies, Boeing, and Lockheed Martin. In the larger Fortune 500 there are eight, and in the Fortune 1000 there are sixteen.

And why has that happened? It started in the early fall of 1993 when Defense Secretary Les Aspin invited a group of fifteen defense industry leaders to a dinner at the Pentagon. William Perry, Aspin’s then-deputy secretary (and eventual successor), gave a presentation. As predicted, the industry leaders did not like it. Across the defense industry this meeting came to be known as “the last supper.”

Perry’s message was simple. Although there had already been major cuts to defense acquisition programs by the President George H. W. Bush administration, more were coming. With the fall of the Berlin Wall in November 1989, and the reduction of Cold War tensions, many previously planned defense programs had already been curtailed or cancelled, but Perry showed that these previous cuts were not an end, but just a beginning.

In short, many of the large projects the executives attending the dinner had booked were going to end early for the “convenience of the government.”

Two programs would become notable examples: Northrop’s B-2 stealth bomber – cut from 132 aircraft to 20, and General Dynamics’ Seawolf submarine – reduced from 30 ships to three. These cuts left both companies with workforces and infrastructure they could not support.

The end of the Cold War seemed to justify many of these cuts. Pausing modernization efforts was seen as a reasonable risk. But the risk calculus being used did not fully accommodate the possibility that once shuttered sophisticated production facilities would be difficult to re-establish.

At the dinner, Aspin and Perry told the defense executives to reduce overhead, close facilities, and consider consolidating. But they offered no direction on how this consolidation should proceed; they simply said, “do it.” And for the next five years they did.

Some Pentagon officials assert that the industrial drawdown and consolidation was “planned.” It was not. The U.S. government started the process, and then halted it. What happened between 1993 and 1998 was a haphazard set of decisions made by business leaders based on market and company financial conditions, without a grand plan provided by the government, just a beginning and an end.

William Perry himself would confess as much in 2016. Looking back, Perry felt, “We would have been better off with more, smaller firms than with a few large ones.” But Norm Augustine of Lockheed Martin countered that Perry’s outcome was never in the cards, stating, “The choice we have been given is more precisely characterized as one between having ten weak competitors with dubious futures, or two strong ones with hopeful futures.”

Still, the reduction initiated at the last supper for the private entities is only one part of the story. Occurring simultaneously was the congressional Base Re-alignment and Closure process – commonly known as “BRAC.” The five BRAC “rounds” closed some 350 military facilities, including several government-owned production sites, most significantly — ammunition plants and shipyards.

This was also a major change. During World War I and later in World War II, the United States government set up some 92 ammunition plants. But after World War II, as one would expect, many of these were quickly closed. By 1964, there were 26 active plants, but only 16 by the end of the Cold War. Today there are five, all government-owned facilities that are operated by contractors.

The shipyard situation is even more telling. At the end of World Wat II, the Navy maintained and operated twelve naval shipyards capable of both designing and constructing warships. Today there are four, mainly due to BRAC.

Presently, the Navy is dependent on only nine yards – five privately owned and operated plus the four public yards. But the public yards do not do original design and construction. Their role is limited to nuclear re-fueling, repairs, and overhauls. The five private yards, all owned by defense industry majors General Dynamics and Huntington Ingalls, handle initial design and construction.

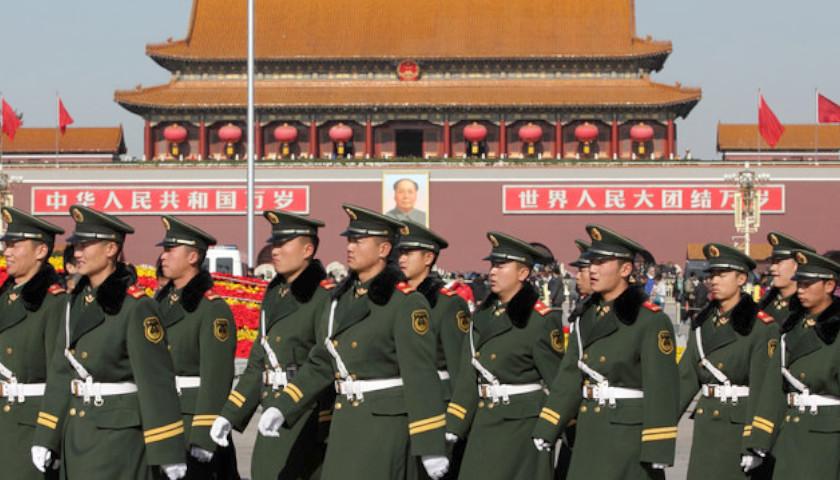

Such a small base makes it difficult to expand ship construction sufficiently to move the Navy to the 320-ship fleet it desires. All while the Chinese navy has become the largest in the world, maintaining a much larger shipyard base to grow even larger.

Since World War II, the American shipbuilding industry – called into duty during the war – is largely gone replaced by Asian shipyards. The few remaining U.S. yards largely only exist because of the Jones Act, a piece of World War I legislation that requires ships carrying goods between American ports be American built and crewed. Navy efforts to utilize the few remaining smaller yards have not been successful.

These limitations are aggravated by another reality. Since modern military and naval systems are enormously more sophisticated than in the past, they take considerably longer to build. During World War II the Essex-class aircraft carriers became a mainstay of the Pacific campaign. Fourteen of the eventual twenty-four ships in this class came into service before the end of the war.

The Essex-class story contrasts with the current production of the Ford-class carriers. The Newport News Shipyard that built eight of the Essex-class carriers in the four years between 1941 and 1945, took eight years between 2009 and 2017 to build the USS Gerald R. Ford. Current plans suggest ten years to build the second Ford-class ship. And today Newport News is the only shipyard that can make U.S. aircraft carriers. By contrast, the Essex-class ships were produced in five different yards.

So where does all that leave us? As many have said, the first step to solving a problem is the recognition that there is one. Such recognition is not always apparent. Although many national security analysts were far from surprised at Russian President Vladimir Putin’s invasion of Ukraine in February 2022, the course of the war itself has been something of a revelation. Few anticipated it would last this long, nor that it would consume such enormous quantities of munitions and artillery ammunition. The global ambitions of China have been more predictable.

Five years after the end of World War I, President Calvin Coolidge, at the urging of New York financier Bernard Baruch, who had chaired the War Industries Board during WWI, established the Army Industrial College for training military officers to interact with industry and hopefully ensure that the slow mobilization of WWI was not repeated. Baruch stated, “I want to establish a little school… to preserve experience and keep in touch with industry.”

Originally, Baruch’s “little school” had a major mission: studying industrial mobilization in time of war. The original concept of the school succeeded. By December 1940, as Europe was once again engulfed in war, and dark clouds were gathering in the Pacific, President Franklin Roosevelt declared that the United States would have to be the “Arsenal of Democracy.” And it was.

But over time, the “little school’s” mission shifted from studying industrial mobilization to merely educating leaders to manage logistical resources.

Perhaps the time has come for industrial mobilization to again receive the attention Baruch intended. We need to know “what we have, what we need, and how and where we can get it.” We need to understand fully the key sources of both raw materials and key components. The Defense Department needs to better understand the financial motivations and risk assessments of commercial firms in the defense market. It may be that the government will have to consider sustaining excess capacity in certain key areas, capacities that seemingly have no immediate need but would be essential during a complex, protracted conflict.

The Pentagon will soon release a revised National Defense Industrial Strategy. Like similar efforts, it is likely to be more aspirational than operational – but it’s a necessary start. And we need to get started.

– – –

M. Thomas Davis is a retired Army Colonel who worked on major pentagon budget issues. He is also a retired senior defense industry executive.